Manager Zhou

Leave a message

Overview

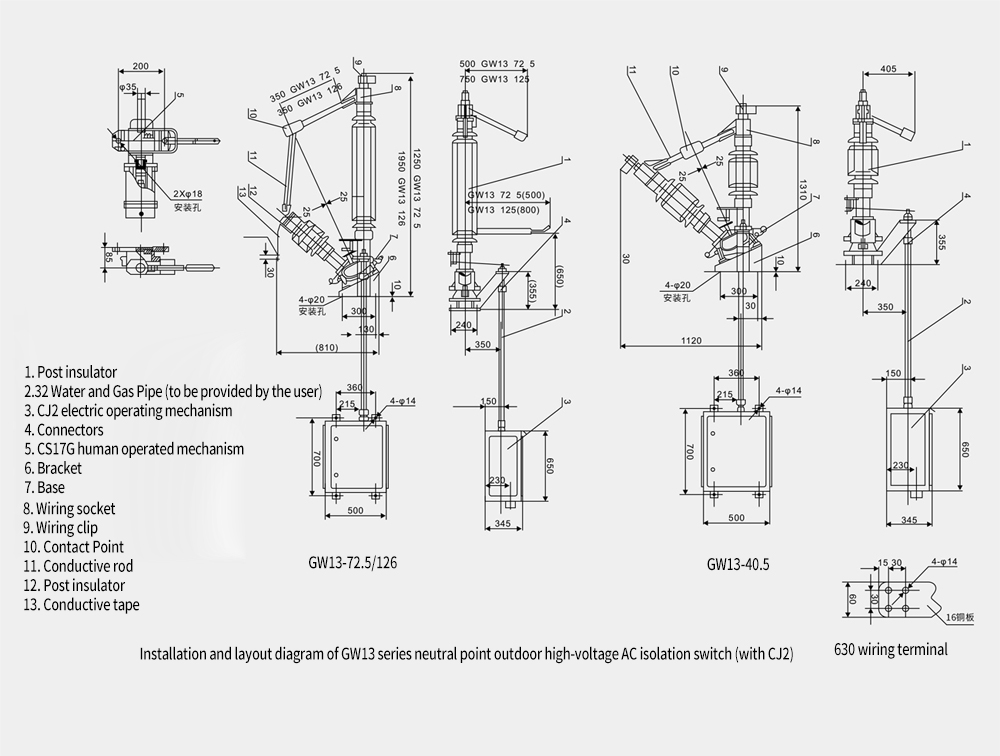

The GW13 series Neutral point isolation switch is used for connecting the neutral point of the transformer under no-load conditions. When the switch blade is in the normal opening position, it can provide an insulation distance that meets safety requirements. The output shaft of the operating mechanism can rotate horizontally by 180 degrees, and the positioning device on the operating mechanism can ensure that the contact and the static contact are in the correct position or disconnected position.

This neutral point isolation switch meets the requirements of GB1985 "AC High Voltage Isolation Switches and Grounding switches" and IEC-129 (1984) standards. It has reliable performance, safe operation, simple structure, and easy installation and adjustment. Widely used in 63KV-110KV substations. Main products: GW13-40.5/630-8

Normal operating environment

◇ Altitude not exceeding 1000m;

◇Surrounding air temperature: upper limit+40 degrees, lower limit -40 degrees;

◇The wind pressure does not exceed 700Pa;

◇The seismic intensity shall not exceed level 8;

◇The thickness of ice cover shall not exceed 10mm;

◇The pollution level of post insulators: ordinary type is level 0, and the pollution resistant type is according to user requirements.

Characteristic

Improved the structure of the bearing turntable, enabling the bearing seat to achieve waterproof function. And equipped with oil injection holes and adjustment screws, the switch has strong integrity and is easier and more convenient to maintain.

Copper brazing technology is used between the conductive rod and the contact, as well as between the conductive rod and the contact finger holder. In addition, soft connections are added between the contact finger and the contact finger holder to significantly reduce the main circuit resistance of the product compared to screw connections, thereby reducing the heating problem of the contact during operation. The grounding rod is made of aluminum alloy with excellent conductivity, and the contact part is made of copper casting. Soft connections are installed at the connection between the conductive rod and the base, as well as between the grounding contact finger and the contact finger seat, greatly enhancing the conductivity of the grounding circuit.

The conductive exposed parts are treated with a surface treatment process of silver plating on purple copper, which results in a smooth, beautiful, corrosion-resistant, and durable surface.

Improved shaft and hole fitting method: The iron and copper fitting has been changed to copper and copper fitting or stainless steel and copper fitting, which solves the biting phenomenon that occurs during long-term outdoor use. Exposed standard components are made of stainless steel; The metal parts are treated with hot-dip galvanizing to enhance the corrosion resistance of the switch.

Technical Parameter

| Name | Unit | GW13-40.5 | GW13-72.5 | GW13-126 |

| rated voltage | kV | 40.5 | 72.5 | 126 |

| Rated current | A | 630 | 630 | 630 |

| Rated short-time withstand current 4S | kA | 8 | 20 | 20 |

| Rated peak withstand current | kA | 20 | 50 | 50 |

| Rated short-circuit duration | S | 2 | 2 | 2 |

| 1-minute power frequency withstand voltage (effective value) | kV | 80 | 140 | 95 |

| Lightning impulse withstand voltage (peak) 1.2/50 μ s | kV | 185 | 325 | 250 |

| Operating torque of human resources institutions | N.m | 150 | ||

| mechanical life | 次 | 2000 | 2000 | 2000 |

| Minimum insulation gap after disconnection | mm | ≥375 | 675 | ≥1050 |

| Main circuit resistance | μΩ | 180 | 200 | 250 |

| Unipolar weight | kg | 120 | 125 | 150 |

| Supporting organization | CS17G manual mechanism or CJ6, CK7 electric mechanism | |||

Click here to watch the indoor isolation switch assembly video

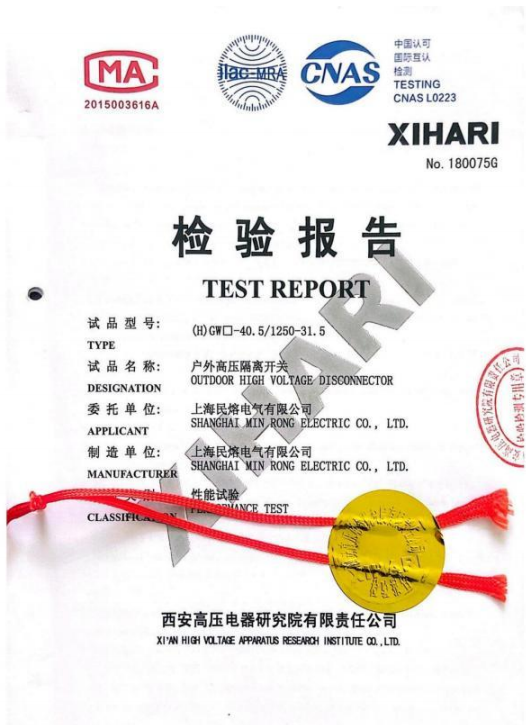

Test report

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)