During a night patrol at a 500kV substation, maintenance staff heard a faint discharge sound from a transformer bushing. Assuming it was surface flashover due to the foggy conditions, they planned a cleaning for the next day. However, within hours, the busing exploded, causing the transformer to trip and resulting in a two-week outage for repairs. Post-analysis revealed a barely visible fine crack at the root of a porcelain shed. Moisture had infiltrated the crack, gradually developing into internal breakdown discharge, ultimately leading to complete failure.

Why Are Shed Cracks So Dangerous?

High-voltage bushings are not solid; they are hollow and filled with insulating oil or SF6 gas. Cracks on the sheds, especially those extending to the metal flange, create a direct pathway for external moisture and contaminants to reach the internal insulation.

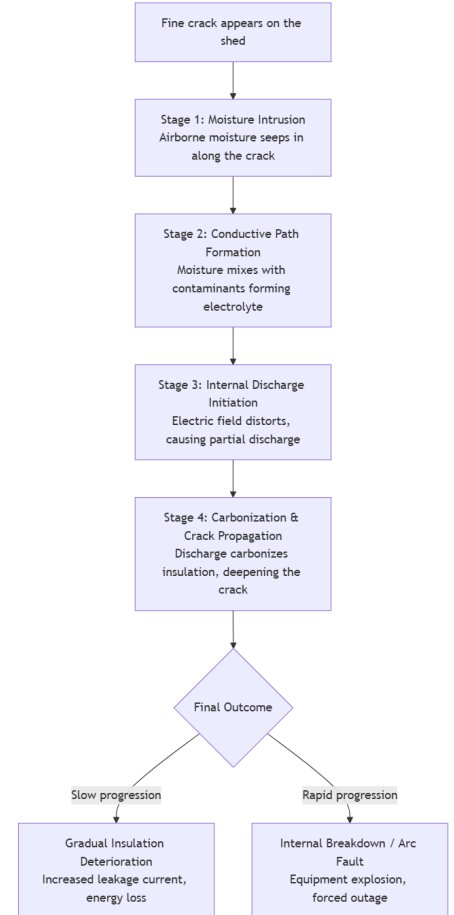

The danger path of a crack is a continuously worsening process, as shown in the following flowchart, ultimately leading to catastrophic failure:

How to Properly Check for Shed Cracks?

When you hear a discharge sound or during routine inspections, follow these steps:

1. Timing and Environment

- Best Time: Dawn or dusk, using a flashlight with oblique illumination. The angled light creates shadows, making cracks more visible.

- Weather Conditions: After rain or in fog, cracks may absorb moisture or collect contaminants first, making them easier to spot.

- Safety Distance: Always maintain a safe distance. Use binoculars or a high-resolution camera for close observation.

2. Key Areas to Inspect

- Shed Roots: The area of highest stress concentration, most prone to cracking.

- Between Sheds: Check for longitudinal cracks connecting multiple sheds.

- Metal Flange-Porcelain Interface: Check the cement filling for cracks or crazing.

3. Crack vs. Contamination Discharge

Characteristic | Surface Contamination Discharge | Crack-Induced Discharge |

Sound | Continuous "hissing" sound | Irregular discharge with faint "cracking" sounds |

Visual | Discharge crawls along the surface, spread out | Discharge is localized, usually fixed at the crack |

Night Observation | Diffuse blue corona glow | Possible intense bright spots of discharge |

Weather Influence | Significantly worse in damp weather | Worse in damp weather but may persist in dry conditions |

What to Do If You Find a Suspect Crack? Emergency Procedure

1. Report Immediately: Report the situation (equipment ID, phase, crack location, initial assessment) to dispatch and management.

2. Enhanced Monitoring: If an immediate outage isn't possible, set up a safety perimeter and arrange regular remote monitoring (e.g., using an infrared thermometer to check for temperature changes).

3. Request Outage: Apply for a planned outage for detailed inspection ASAP. For critical equipment, consider load transfer before de-energization.

4. Professional Testing: After de-energization, technicians should confirm using:

- Visual Inspection: Use a magnifying glass for careful examination.

- Ultrasonic Testing: Perform non-destructive testing on the porcelain to detect internal flaws.

- Insulation Resistance Test: Measure the insulation resistance of the main insulation and tap (if applicable), compare with historical data.

Preventive Maintenance Suggestions

1. Create a Specific Checklist: Include bushing shed crack inspection in monthly routine patrols and special inspections (e.g., after strong winds or earthquakes).

2. Improve Technical Records: Maintain a file for each bushing with photos from each inspection to track potential crack propagation.

3. Adopt Advanced Tools: Implement drone-based HD imaging and UV imaging (corona discharge detection) to identify invisible defects early.

Summary: Safety First, Prevention is Key

The "hissing" discharge from a high-voltage bushing is its final alarm. Maintenance personnel must remember:

Listen, look, and differentiate, shed cracks are key.

Use angled light to find traces, keep a safe distance.

If you suspect a crack, report it immediately—don't wait.

Never assume it's just dirt; the consequences are too great.

Final reminder: One thorough inspection is better than ten emergency repairs. Always err on the side of caution when dealing with insulation defects in high-voltage equipment.

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)