During a power outage switching operation at a substation, a maintenance worker found the earthing switch could not be engaged. Attempting to force it, they bent the steel plate around the operating hole and completely damaged the interlock mechanism. The root cause was later found to be a single rusted pin. This act of "forcing" not only caused tens of thousands in repairs but also extended the outage by six hours.

Why You Must NEVER "Force It"

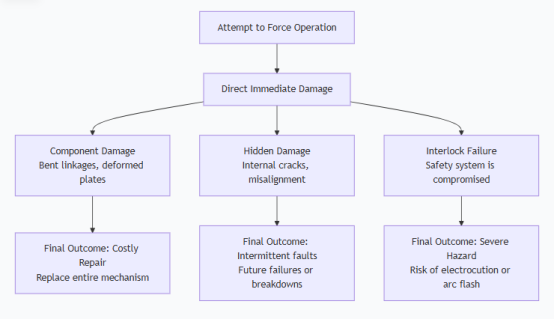

The Five-Prevention interlock is a critical lifeline for personnel and equipment safety. Forcing it can have catastrophic and expensive consequences, as shown in the following sequence of failures:

Check These 3 Key Mechanical Components First

When you encounter operating resistance, stop immediately and inspect these parts in order:

1. Interlock Links & Latches (The Most Critical Transmission Parts)

- Location: Behind circuit breaker compartment doors, cable compartment shutters, or inside the earthing switch mechanism.

- Common Problems:

- Bent or Deformed: Caused by impact or long-term stress, preventing smooth sliding.

- Rusted or Seized: Due to a humid environment, making moving parts stuck.

- Loose Mounting Screws: Causes the link to shift and fall out of its intended path of travel.

- How to Check: Open the compartment door and observe if the interlock link is straight. Gently try to move it with a finger or screwdriver to feel if it moves smoothly without obstruction.

2. Earthing Switch Operating Shaft & Crank Arm (The Most Prone to Rust)

- Location: The long shaft connecting the operating hole to the earthing switch blades and the connecting crank arms.

- Common Problems:

- Dry Bushings: Lack of lubrication causes increased operating torque.

- Loose Crank Arm Screws: Creates excessive mechanical play, preventing the interlock from releasing properly.

- How to Check: Look for old, dried-up, or contaminated grease on the shaft and arms. Tapping gently with a soft mallet can sometimes loosen minor rust (use with caution).

3. Program Lock / Mechanical Interlock Bolt & Spring

- Location: The mechanical program lock on the cabinet doors.

- Common Problems:

- Stuck Bolt: The locking bolt is jammed by dust, grime, or rust.

- Fatigued Spring: The internal spring is weak or broken, failing to provide enough force for operation.

- How to Check: When using the correct key, pay attention to if it rotates unusually hard. Observe if the bolt action is crisp and positive when locking or unlocking, without hesitation.

Quick On-Site Troubleshooting & Lubrication Guide

If you find a problem, you can try these safe methods:

1. Cleaning: Use a blower or dry compressed air to remove dust and debris from the mechanism.

2. Lubrication: Apply penetrating oil to rusted parts to dissolve rust. Once movable, spray on specialized grease (e.g., white PTFE spray). Avoid common machine oil as it attracts dust and will worsen jamming later.

3. Tightening: Check and tighten all visible screws and pins.

4. Manual Assistance: For a heavy earthing switch, one person can operate the handle normally while another gently taps the bearing block or crank arm with a wooden or rubber mallet to help it overcome initial resistance.

When Must You Report the Problem?

Stop immediately and report the defect to professional maintenance if:

- Operations remain stuck after the simple treatments above.

- You find interlock links that are visibly bent, cracked, or with broken welds.

- You hear metallic cracking sounds from inside the mechanism.

- The operating force feels uneven and jerky.

Summary: Maintenance Mantra

Remember this mantra when the interlock won't operate:

> Don't force, stop the operation.

> First check links, then shafts and pins.

> Clean and lubricate, tap with vibration.

> If it still won't budge, make the notification.

Final reminder: The Five-Prevention interlock is the bottom line for safety. Treat every fault with respect. A patient inspection is always better than a forceful action.

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)