Manager Zhou

Leave a message

10kV Three core intermediate joint

| product name | model | Applicable conductor cross-sectional area(mm2) |

| 10KV Three core cold shrink Intermediate Joint | JLS-10/1.1 | 25-50 |

| JLS-10/1.2 | 70-120 | |

| JLS-10/1.3 | 150-240 | |

| JLS-10/1.4 | 300-400 | |

| 10KV three core cold shrink indoor Terminal | NLS-10/3.1 | 25-50 |

| NLS-10/3.2 | 70-120 | |

| NLS-10/3.3 | 150-240 | |

| NLS-10/3.4 | 300-400 | |

| 10KV three core cold shrink outdoor terminal | WLS-10/3.1 | 25-50 |

| WLS-10/3.2 | 70-120 | |

| WLS-10/3.3 | 150-240 | |

| WLS-10/3.4 | 300-400 |

Details of accessories for Cold shrink cable accessories

Cold shrink terminal | Semi conductive tape | Silicone grease paste | Cleaning paper | paper card |

Protective casing | underfill | PVC | Band-aid | Installation process |

sealed tube | Weaving ground wire | Color Circle | J-20 | certificate of conformity |

constant force spring | tape measure | Construction gloves | ribbon | Insulating tube |

Cold shrink cable accessories (power cable accessories) Product feature:

1. Simple installation method: The entire product adopts full cold shrinkage technology. During the installation process, simply pull the wire core, and the elastic body will quickly shrink and tightly adhere to the desired installation position.

2. Stress evacuation effect: After installation, it always maintains appropriate radial pressure on the cable body, tightly connecting the internal interfaces to prevent electrical breakdown due to breathing effects during cable operation. The stress control part is combined with the main insulation to effectively solve the problem of electrical stress concentration on the outer shielding surface of the cable, ensuring reliable insulation and safe operation.

3. Safe and time-saving: No special training required, simple installation and operation, no need for hot work. The fully cold shrink automatic reset technology is easy to install, does not sweat, greatly reduces quality accidents caused by improper operation, and solves the problem of loose or mismatched prefabricated cable accessories.

4. Wide application scenarios: Due to its anti pollution, aging resistance, good hydrophobicity, and excellent heat and cold resistance, it is particularly suitable for high-altitude areas, cold areas, humid areas, salt spray areas, and heavily polluted areas. During the installation process, open flames are not allowed, especially suitable for flammable and explosive places such as petroleum, chemical, mining, and tunnels.

5. Reliable performance: The equipment has excellent quality and high degree of automation.

6. Beautiful appearance: using extended cold shrink tubing and seamless thread.

Applications

Power Distribution Networks

- Underground cable system repairs and extensions

- Utility distribution line connections

- Cable fault restoration and maintenance

Industrial Applications

- Factory power distribution systems

- Mining and industrial plant power networks

- Large commercial complex power supplies

Infrastructure & Construction

- Building service connections

- Tunnel and subway power systems

- Renewable energy project connections

Installation & Maintenance

Installation Requirements

- Clean, dry conditions during installation

- Proper cable preparation following manufacturer guidelines

- Correct application of sealing compounds

- Adequate working space and safety precautions

Quality Assurance

- Visual inspection before, during, and after installation

- Proper dimensional verification of cable preparation

- Verification of all sealing systems

- Compliance with manufacturer's installation guidelines

Maintenance Features

- Minimal maintenance requirements

- Visual inspection capability

- Compatible with standard test procedures

- Long-term reliability under normal operating conditions

Why Choose Our 10kV JLS-10 Intermediate Joint?

Proven Reliability

- Extensive type testing

- Field-proven performance in various environments

- Consistent quality across production batches

Technical Support

- Comprehensive installation training programs

- Detailed technical documentation and installation guides

- On-site support for critical installations

- Rapid response to technical queries

Quality Manufacturing

- State-of-the-art manufacturing facilities

- Strict quality control at every production stage

- Traceable materials and components

- Continuous product improvement based on field feedback

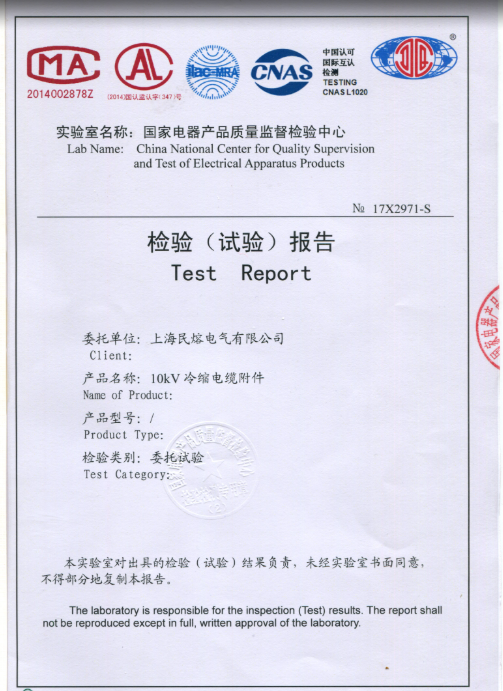

Test Report on 10kV Cold Shrink Cable Accessories

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)