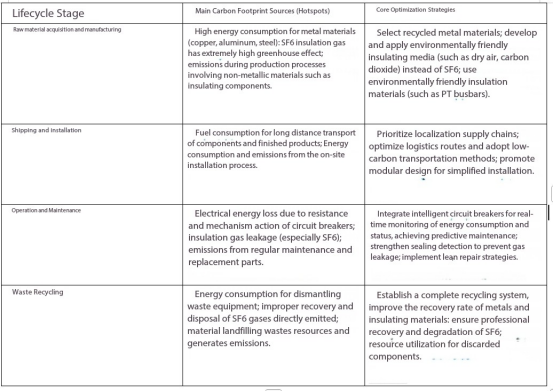

As a key equipment in the power system, the carbon footprint management and optimization of Circuit breakers throughout their entire lifecycle are crucial for the green transformation of the power industry. The table below summarizes the carbon footprint hotspots and optimization strategies for each stage of the circuit breaker lifecycle, helping you establish a comprehensive concept first.

Master the standards and methods of carbon footprint accounting

At present, relevant standards and methodologies are constantly being improved.

1. Accounting standards and specifications: In recent years, group standards for the types of carbon footprint products (PCR) and quantification methods for electrical equipment have been released, providing important basis for accounting. For example:

T/CMEPCA 061-2025 "Methods and Requirements for Quantifying the Carbon Footprint of Greenhouse Gas Products - Circuit Breakers" provides methods and requirements for quantifying the carbon footprint of circuit breaker products.

T/CMEPCA 081-2025 "Product Carbon Footprint Product Category Rules 3.6kV~40.5kV AC Metal enclosed switchgear and Control Equipment" covers switchgear including circuit breakers.

These standards typically require a methodology based on Life Cycle Assessment (LCA), covering all stages from cradle to grave.

2. Accounting Model and Parameters: The patent (CN117196389B) of Southern Power Grid Energy Development Research Institute Co., Ltd. provides a specific accounting method. This method divides the lifecycle of circuit breakers into working stage, maintenance stage, and disposal stage, and calculates the carbon footprint of each stage by establishing a detailed mathematical model. For example, the formula for calculating the carbon footprint (C1) during the work phase is: 'C1=(D1+D2) F1', where D1 is the normal usage power consumption, D2 is the power consumption in the open circuit state, and F1 is the power emission factor. This method considers the different states of equipment operation and improves the accuracy of accounting.

Key strategies for implementing carbon footprint optimization

Based on the accounting results, efforts can be made to optimize the carbon footprint of circuit breakers from the following aspects:

1. Technological innovation: replacing high impact materials

Accelerating the elimination of SF6 gas: SF6 is an extremely strong greenhouse gas. The fundamental solution is to use natural ester insulating oil, dry air (such as "dry air insulated circuit breaker cabinets"), or carbon dioxide (CO2) as insulation and arc extinguishing media. For example, Hitachi Energy's EconiQ series high-voltage combination uses a mixture of CO2 and O2 gas, which basically eliminates the carbon dioxide equivalent emissions related to insulation gases.

Promote environmentally friendly materials and ecological design: Consider environmental friendliness in the product design stage. For example, ABB's VD4 vacuum circuit breaker uses innovative environmentally friendly insulation materials (PT poles), which can be recycled, degraded, and reused, and has passed the China Environmental Labeling (Type II) certification and carbon footprint certification.

2. Intelligence and digitalization: improving operational efficiency

Deploy intelligent circuit breakers (such as ABB's iVD4) ? Real time monitoring of current, voltage, power, and the health status of the circuit breaker itself. These data help:

Identify energy efficiency optimization space: Identify abnormal energy consumption patterns and guide energy-saving renovations.

Realize predictive maintenance: Change from "regular maintenance" to "on-demand maintenance", avoid unnecessary maintenance activities and shutdowns, and reduce the resulting carbon emissions. It is said that such a plan can reduce the risk of accidents by 30% and reduce operational costs by 50%.

3. Improve the recycling and resource utilization system

Establish a nationwide circuit breaker recycling network to ensure that scrapped equipment can enter formal disposal channels.

Develop and apply efficient disassembly and classification technologies to improve the recovery and reuse rates of metals (such as copper, aluminum, steel) and insulation materials. In carbon footprint accounting, the carbon reduction (Rez) brought about by recycling is considerable.

Professional recycling and purification technology must be used for the collected SF6 gas to achieve recycling or harmless treatment.

Typical case: SF6 circuit breaker vs. dry air circuit breaker

A comparative analysis has been conducted on the circuit breaker cabinets in 12 kV gas insulated ring network switchgear

In the raw material acquisition stage, if the production of insulation gas itself is not considered, the dry air insulated circuit breaker cabinet may require more materials due to its structure, and its carbon emissions are about 25% higher than SF6 circuit breaker cabinets.

However, once the enormous carbon emissions caused by the extremely high global warming potential (GWP) of SF6 gas are taken into account, the entire lifecycle carbon footprint of SF6 circuit breaker cabinets will far exceed that of dry air circuit breaker cabinets, with a huge difference. This highlights the urgency and enormous potential of phasing out SF6 in carbon reduction.

I hope this detailed interpretation can provide practical assistance for your work. If you want to delve deeper into the carbon footprint analysis of specific voltage levels or specific models of circuit breakers, we can continue to explore.

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)