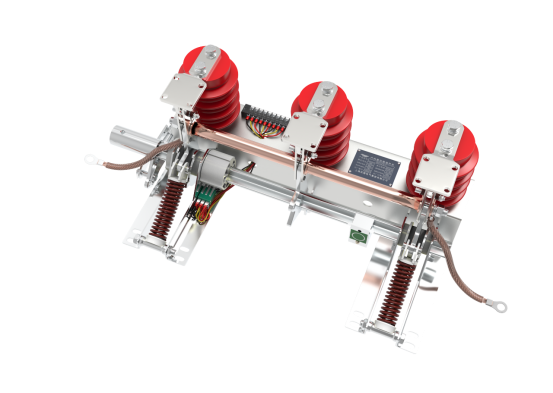

At 1:15 am, the substation monitoring system issued a piercing alarm - the 35kV bus grounding signal flickered, and the JN15-12 Grounding switch inexplicably tripped again. This is already the third time this month.

As the on duty supervisor, my team and I immediately put in the investigation. After 3 hours of intensive maintenance, it was finally discovered that the root cause of the malfunction was a disconnect spring worth only 8.5 yuan that had broken due to metal fatigue.

Fault phenomenon: Seemingly complex systemic issues

-Surface symptoms: frequent tripping and irregular operation of the grounding switch

-Protection device: Display "Control circuit disconnected" and "Operation timeout"

-Preliminary judgment: The operation and maintenance personnel first suspect that it is a motor malfunction or a secondary circuit problem

Troubleshooting Process: The Path from Complex to Simple Diagnosis

flowchart TD

A [JN15 grounding switch frequently trips] -->B [Step 1: Check the secondary circuit]

Measure control voltage, check wiring Terminals]

A -->C [Step 2: Check the motor mechanism D [Result: Everything is normal]

C -->E [Result: Everything is normal]

D -->F [Step 3: Mechanical Characteristics Test]

Measurement of opening and closing time, synchronicity]

E --> F

F -->G [Abnormal extension of opening time found]

Extended from standard 0.8s to 3.2s

G -->H [Step 4: Manual Operation Check]

H -->I [significantly abnormal hand feel]

The opening process lacks elasticity and force

I -->J [Final step: Open cover inspection]

J -->K [Discovered that the opening spring was broken]

Caused by metal fatigue

Root cause analysis of spring fracture

1.Material fatigue: After long-term (more than 5 years) frequent operation, the metal material of the spring experiences fatigue

2. Corrosion environment: The outdoor environment of the substation accelerates the oxidation of the spring surface

3. Quality defects: Non original parts, substandard heat treatment process

4. Maintenance deficiency: Spring maintenance does not include spring inspection items

Prevention and Maintenance: How to Avoid Similar Accidents

Key points of daily inspection

-Manual operation test: Perform manual opening and closing operations at least once a month to feel the spring force

-Sound monitoring: During normal operation, a crisp "click" sound should be heard, but in abnormal situations, the sound may be dull

-Appearance inspection: Check the spring for signs of rust and deformation through the observation hole

Regular maintenance projects

Maintenance project | Standard cycle | Inspection content |

Spring performance test | 1 year | Measure the opening time and check the elasticity coefficient |

Institutional lubrication | 2 years | Clean and replace special lubricating grease |

Overall inspection of operating mechanism | 3 years | Comprehensive disassembly inspection, replacement of vulnerable parts |

Suggestions for spare parts management

1.Reserve of key small parts: low-priced but essential components such as springs, washers, and pins must be kept in stock

2. Priority should be given to original accessories: Do not lose the big deal for small things. Key parts such as springs must be sourced from the original factory or certified suppliers

3. Service life registration: Establish a ledger of the service life of key small parts and replace them in advance before expiration

Emergency response plan

When a similar tripping fault occurs, the following process can be followed to quickly handle it:

1. Immediately disconnect the power supply and hang a "No Operation" sign

2. Use a multimeter to measure the resistance of the control circuit

3. Flexibility of manual operation testing mechanism

4. Check the contact status of the auxiliary switch

5. Finally, check if there is any obvious damage to the spring mechanism

Economic Benefit Comparison

Project | Spring Replacement Plan | Whole Switch Replacement Plan |

Material cost | 8.5 yuan | 8000-12000 yuan |

Labor cost | 2 people x 1 hour | 4 people x 4 hours |

Power outage losses | basically avoidable | at least 4 hours |

Total cost | Approximately 500 yuan | Approximately 15000 yuan |

summary

This repair experience once again validates the "weakness theory" of the power industry: the reliability of the entire system often depends on the most inconspicuous component. For grounding switches like JN15, the spring is their Achilles heel.

Suggestions for each substation:

1. Establish a list of key small parts and regularly inspect and replace them

2. Strengthen the training of maintenance personnel and raise awareness of the importance of small parts

3. Improve spare parts management to ensure that critical small parts are available at all times

Next time when your grounding switch encounters a similar problem, you may want to check this small spring that is only worth a few dollars but can determine the fate of the system - it may be the key to solving the problem.

The reliability of power equipment depends not only on the most expensive components, but also on the weakest link.

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)