In the 10kV distribution network of a coastal chemical industry park, seven flashover failures of porcelain insulators occurred within one year due to salt fog corrosion and contamination. After being replaced with FPQ composite pin insulators, not a single pollution flashover accident occurred for five consecutive years, and cleaning maintenance costs dropped to almost zero. Behind this lies the complete innovation of traditional electrical porcelain technology by composite material science.

1. What is an FPQ Composite Pin Insulator?

An FPQ composite pin insulator is a new type of line insulator composed of a fiber-reinforced resin pulltruded core rod, silicone rubber weathersheds, and metal end fittings. Its name typically represents its characteristics:

- F: Composite (Material)

- P: Pin-type

- Q: Silicone Rubber

It essentially combines the excellent performance of silicone rubber composite long-rod insulators with the installation method of traditional pin-type insulators.

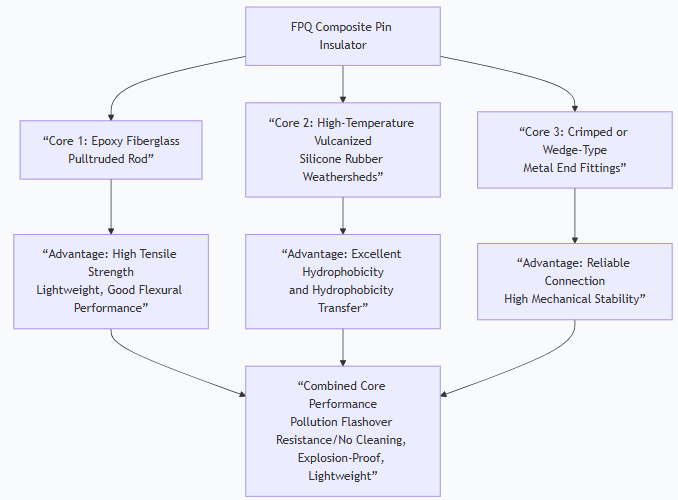

Its performance stems from its unique materials and structure. The core composition and source of advantages are illustrated in the chart below:

2. Core Performance Analysis: Why Replace Porcelain Insulators?

1. Excellent Pollution Flashover Resistance

This is its core value.

- Hydrophobicity: The silicone rubber material itself has a large water contact angle, preventing the formation of a continuous water film on its surface and instead forming isolated water droplets, greatly suppressing the formation of leakage current.

- Hydrophobicity Transfer: More importantly, silicone rubber can "transfer" its hydrophobicity to the contaminants adhering to its surface. Even after long-term operation and accumulation of pollution, the surface of the contamination layer retains a degree of hydrophobicity, maintaining very high insulation strength even in humid environments.

- Comparison: The surface of porcelain insulators is hydrophilic. In humid weather, the contamination layer absorbs moisture forming a continuous conductive film, easily leading to flashover.

2. High Mechanical Strength and Impact Resistance

- High Strength: Its core rod is made of epoxy resin and glass fiber, with an axial tensile strength exceeding 600 MPa, which is 2-3 times that of ordinary steel and 5-8 times that of high-strength porcelain.

- Good Flexural Performance: Manufactured using a pulltrusion process, it offers strong resistance to bending and torsion, effectively resisting dynamic loads such as wind swing and ice loading, making it particularly suitable for large conductor or long-span applications.

- Explosion-Proof and Brittle Fracture Resistance: Composite insulators undergo ductile fracture. Even if accidentally damaged, they do not shatter explosively like porcelain insulators, which can cause the conductor to fall and lead to secondary accidents. This is crucial for lines located above areas with human activity.

3. Superior Corrosion and Aging Resistance

- Acid and Alkali Resistance: Silicone rubber has strong resistance to acid rain in the atmosphere and corrosive gases in chemical industrial areas.

- UV Resistance: High-quality silicone rubber contains UV inhibitors, ensuring it does not crack or powder under long-term outdoor exposure.

- Expected Service Life: The design life provided by mainstream manufacturers is generally 30-40 years.

4. Lightweight and Easy Installation

- Light Weight: The weight of an FPQ is only 1/5 to 1/10 of that of a porcelain insulator of the same voltage grade. This significantly reduces the load on poles/towers and also reduces workers' labor intensity.

- Easy Installation: The installation method is exactly the same as that of traditional pin-type insulators, requiring no special tools. Its lightness allows one person to easily complete the installation.

3. Main Application Scenarios

FPQ composite pin insulators are not a panacea, but they offer irreplaceable advantages in the following scenarios:

1. Highly Polluted and Corrosive Areas (Preferred Choice)

- Coastal Areas: Severe salt fog pollution.

- Industrial Zones: Areas near steel, cement, and chemical plants where the air is filled with conductive dust or corrosive gases.

- Application Value: Eliminates cleaning, saving a lot of routine maintenance costs and water for washing.

2. Applications with High Vibration and Impact Risk

- Long-span, Large-conductor Lines: Strong wind-induced vibration, where the excellent flexural and fatigue resistance of FPQ stands out.

- Lines near Railways and Highways: Vibration from vehicle traffic can loosen the hardware of porcelain insulators or fatigue the porcelain.

3. Areas Requiring Extremely High Safety and Reliability

- Densely Populated Areas, above schools, shopping malls: Their explosion-proof特性 prevents injuries or property damage from falling fragments if the insulator breaks.

- Firebreaks in Forested Areas: Their explosion-proof and pollution flashover resistance effectively reduces the risk of wildfires caused by insulator failures.

4. Capacity Upgrades of Old Lines

- When needing to replace conductors with larger cross-sections, the lightweight nature of FPQ allows for direct replacement without reinforcing or even building new poles/towers, saving significant renovation costs.

4. Selection, Operation, Maintenance Points and Precautions

Selection Points

1. Voltage Rating: Determine the insulator model and structure height based on the system voltage.

2. Creepage Distance: Select sufficient creepage distance based on the pollution level of the installation area. For heavy pollution level IV areas, the specific creepage distance should be ≥31mm/kV.

3. Mechanical Strength: Select the corresponding mechanical load class based on the maximum conductor tension, wind load, etc.

4. Brand and Quality: Choose reputable brands, paying attention to the bonding process between the core rod and weathersheds, and the connection method of the end fittings (crimping is better than bonding).

Operation and Maintenance Points

1. Maintenance-Free is Not Absolute: While cleaning is not required, regular inspection is still necessary.

2. Inspection Focus:

- Weathershed Damage: Check for tearing damage caused by bird pecking or vandalism.

- Electrical Erosion: Check for powdering or whitening of the weathershed near the high-voltage end fitting caused by partial discharge.

- Core Rod Exposure: If the weathershed is damaged exposing the FRP core rod, replace it immediately, as the core rod is not UV resistant and ages rapidly ("brittle fracture") in damp environments.

3. Preventive Testing: Periodically sample and test its hydrophobicity (Spray method, HC1~HC7 grades) and electrical performance.

5. Summary: The Value Proposition of FPQ

Characteristic | Traditional Porcelain Pin Insulator | FPQ Composite Pin Insulator |

Pollution Flashover Resistance | Poor, requires frequent cleaning | Excellent, eliminates cleaning |

Mechanical Performance | Brittle, poor impact resistance | Ductile, high strength, lightweight |

Safety | Risk of explosion | Explosion-proof, fail-safe |

Weight | Heavy | Light |

Lifecycle Cost | High maintenance cost | Slightly higher initial investment, but lower comprehensive cost |

Conclusion:

The FPQ composite pin insulator represents the mainstream direction of development for insulation technology in medium and low-voltage distribution networks. Through advancements in materials science, it fundamentally addresses the three major weaknesses of traditional porcelain insulators: susceptibility to pollution, susceptibility to impact, and heavy weight. For new lines, especially in harsh environments or areas requiring high reliability, directly choosing FPQ is a wise decision. For existing lines with difficult maintenance, using it as a retrofit option can instantly improve power supply reliability and reduce maintenance burdens.

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)